What’s up with the Kawasaki Ninja 400 / Z400 brakes?

The Ninja 400 / Z400 have decent enough brakes for street use, with their 310mm floating front disc. It’s larger in diameter than similar bikes like the Yamaha R3 (298mm). The OEM pads have what seems to be the standard “OEM feel” for budget oriented bike, very wooden, lacking any substantial bite, and requiring a lot of lever pressure to get much stopping force. Probably the cheapest pads Kawasaki could buy in bulk. One of the first things we recommend upgrading when you purchase a Ninja 400 or Z400 is the front brake pads. It’s an inexpensive and relatively easy upgrade and the increase in stopping power and control is substantial.

The larger OEM 310mm rotor, however, is narrower at the brake pad surface than you would find on other bikes, and only 4.5mm thick, so the heat from braking is more concentrated in a smaller amount of rotor metal. Because of this, racers across the world have discovered that while it’s okay for street use and canyon carving, it is unable to dissipate the heat generated during racing and can be warped in a day or less by a fast rider on track.

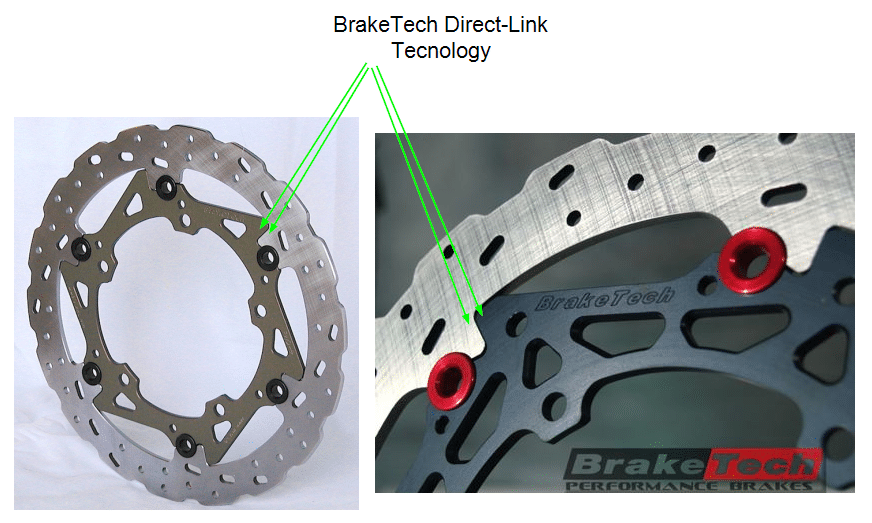

During the 2019 MotoAmerica season, Rocco Landers was going through rotors nearly as fast as brake pads, so we were looking for a better option. He had a pile of warped OEM rotors, as well as Galfer standard 4.5mm and even 3 warped Gafler WSS Spec 5mm rotors. This is when we discovered that BrakeTech had released their Axis/Cobra floating rotor with Direct-Link technology in the thickest size available anywhere, 6mm. We needed to test one! The Direct-Link technology changes the way the rotor behaves under braking force. Typically a floating rotor connects the rotor blade to the carrier with round bobbins. When braking force is applied, it must be transfered through these bobbins to the wheel and these bobbins will flex. BrakeTech changed everything with their Direct-Link technology. Two flat surfaces (one on the rotor blade, one on the center carrier) rest just about 1/4 millimeter apart while the rotor sits so the rotor can float. But when braking force is applied and the bobbins begin to flex, these 2 flat faces come together and prevent additional flex, transferring all of the braking force to the wheel. Brilliant.

He came back in and said that both rotors noticeably outperformed the Galfer 5mm rotor, but he couldn’t tell a difference between the stainless steel and iron. Rocco is incredibly sensitive to the bike and earlier that same day he had felt an issue that we chased for awhile and turned out to be a worn out fork bushing. So if he could feel a worn out fork bushing, I was surprised he didn’t feel a difference with the rotors and I reached out to BrakeTech to ask about it. They confirmed that they had recently improved their stainless steel rotor material and the new material was performing so well that it was at the same level as their iron rotors, but without all the maintenance that comes with iron rotors. The BrakeTech rotors are also a lot less expensive than the Galfer WSS spec rotor (Galfer has since discontinued the 5mm WSS spec rotor) and other high performance European rotors, so that answered that. The BrakeTech Axis/Cobra SS was our new clear top performer! BrakeTech also makes their rotors in a 5mm version, which is still oversized compared to stock and plenty heavy duty for 99% of riders and racers out there, but if you are building a Ninja 400 superbike, or just want the best available, the 6mm is the way to go.

BrakeTech Axis/Cobra SS Front Brake Rotor – Kawasaki Ninja 400

There are dozens of brake pad options out there, and many manufacturers are offering OEM thickness replacement rotors as well as thicker alternatives to accommodate higher temperatures for race use. We have done a few specific tests with brake pads and rotors and have also collected some good information from our race team riders and from Rocco Landers during the 2019 and 2020 MotoAmerica seasons. Here’s what we found:

Brake pads we’ve tested:

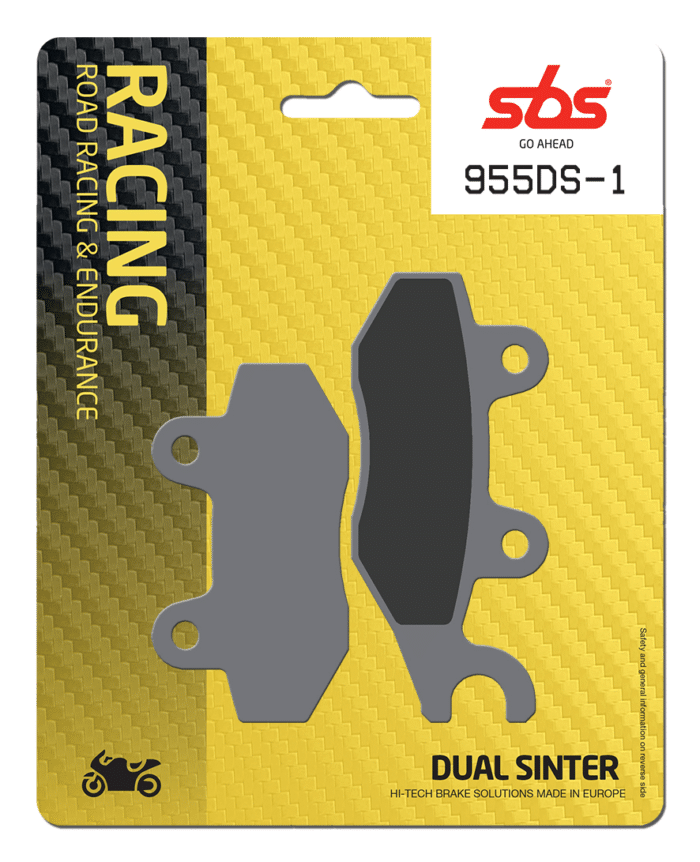

SBS Brakes DS-1 Sintered Pads

Our new top performing brake pad for the Ninja 400 for race use, especially for bikes with increased horsepower. This pad has an almost unbelievable initial bite and stopping force. The huge reduction in lever pressure required to stop the bike dramatically improves rider feel and confidence. Though they are very expensive, this is what I now use on my personal bike. They also bed in quickly.

Our previous top performer and overall best bang for your buck brake pads. These RDP pads perform outstanding hot or cold, and thus, can be used for street or track use. They bed in quickly, and have very good initial bite and predictable stopping force similar or slightly better than the Vesrah ZZ. These are the pads Rocco preferred in our test and used to clinch his second MotoAmerica Junior Cup championship in 2020. At only $59.95, these are our general recommendation for both street riders and track riders or racers on a budget. At this time, Rocco had not tested the SBS DS-1 pad to see if he would have preferred that instead.

Ferodo CPro Carbon Ceramic Race Pads

The Ferodo CPro is ceramic pad, compared to most of the others which are sintered metal. This means that they behave a little differently. The braking characteristics change dramatically when they reach optimum working temperature. So they will feel wooden and lack stopping force when they’re cold, and then suddenly have excellent bite and stopping force when hot. You must keep them hot for them to work, which means they are no good for street or track day riders, and only work well for top level racers. If you keep them hot, they are excellent, with stopping force slightly better than the DP Brakes RDP and better life. They also take a little longer to bed into the rotor, but this is just because they wear slower and will also last a little longer than other sintered pads. But the higher price and inconsistency with temperature makes them less desirable to some.

Vesrah Super RJL-ZZ Race Pads

The Vesrah Super RJL-ZZ is a more expensive pad than the standard RJL and is designed for race use. However, with the Ninja 400, and Yamaha R3, there’s a very small difference in performance between the two pads. In our tests, riders felt that the DP Brakes RDP pads were at least comparable or a little better in stopping power with the same feel and the DP Brakes are considerably cheaper. So we don’t recommend the Vesrah ZZ pads anymore and recommend racers either use the DP Brakes RDP series or spend the extra money for the SBS DS-1 if they want the best stopping power available.

Vesrah RJL

The Vesrah RJL pads have been a favorite of ours for the little bikes since testing them with the Yamaha R3 years ago. They have good life, good initial bite and stopping force, and good consistent lever feel. Their low cost and excellent overall performance still makes them a great purchase. They are good, especially for street and track day use, because from our tests, I think they last longer than the DP Brakes RDP race pads and work almost as well at a good price, and they can also be used for racing and perform very well.

Galfer HH Sintered Race Pads – These Galfer pads were a little disappointing. They lack initial bite and have a similar feel to stock with a bit more braking force once hot.

Galfer also makes a ceramic front race pad which we have not tested, but would also require a decent pace to keep hot enough for good stopping force, similar to the Ferodo CPro ceramic pads, so not good for street use.

You must be logged in to post a comment.